Description

CEREC Primemill is a wet/dry grinding and milling unit ideal for chairside production. CEREC Primemill sets new standards in terms of user-friendliness. The unique design and the technical features make integration into the practice very easy. With CEREC Primescan and the highly automated, intuitive CEREC Software 5, the new, first-class milling and milling unit are the perfect setup and the best time to make your practice fit for the future with CEREC.

Just like the Primescan , the Primemill marks a new generation of CEREC devices. This makes these devices relevant for dentists who want to get into chairside production. These devices are extremely powerful and designed for ease of use. In my opinion, the CEREC Primemill makes entry into the digital practice interesting for almost all practice owners.

– Uwe Herzog

CAD/CAM and CEREC expert

inLab SW 22 offers extended connectivity to CEREC Primemill. inLab Software 22 offers a harmonized new user interface, additional design options, and a symbolic connection to CEREC Primemill. inLab CAM 22 supports CEREC Primemill based on design data from CEREC, inLab CAD, and third-party providers.

CEREC Primemill Benefits:

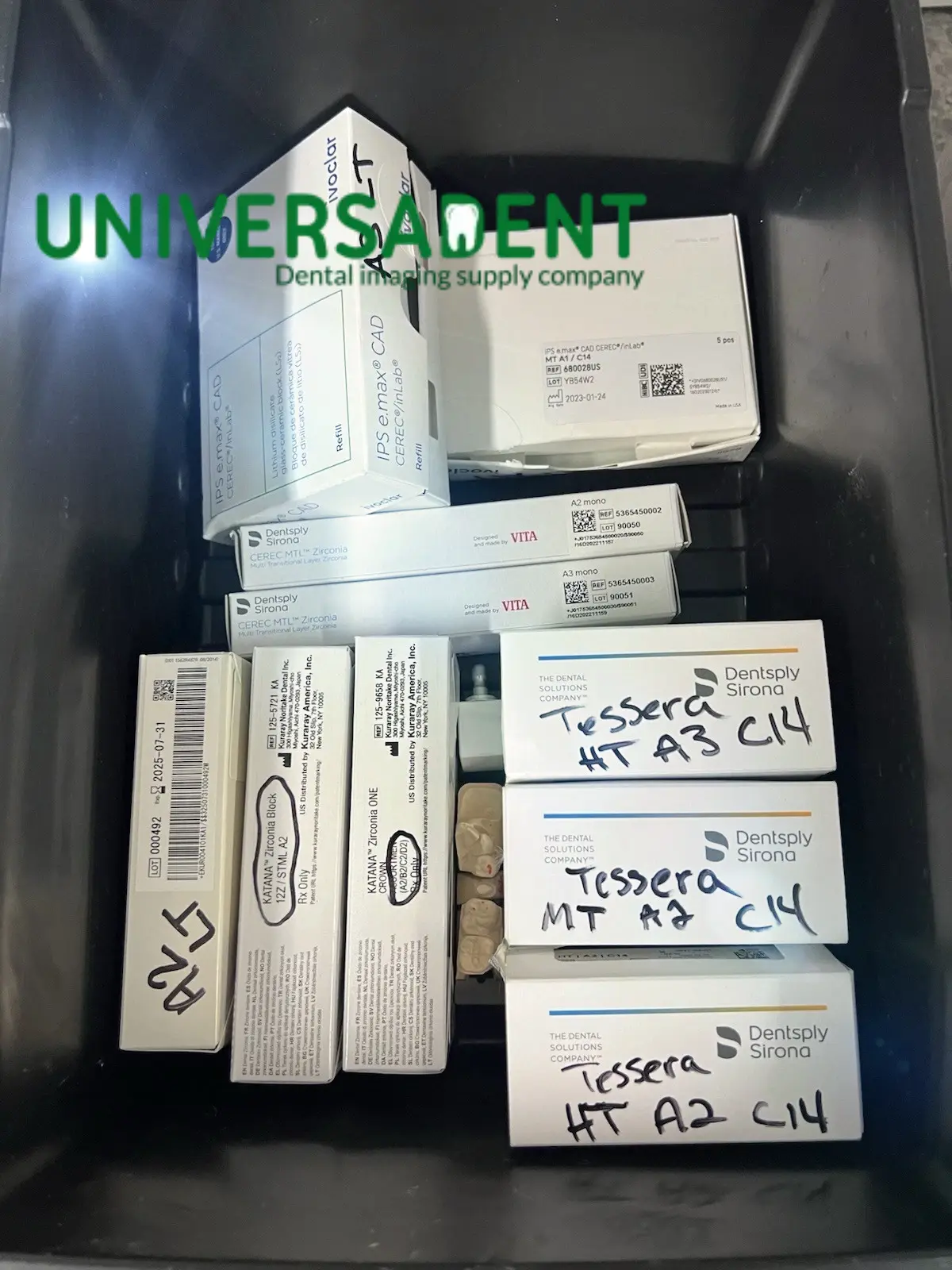

- Dry milling for zirconia and wet milling for a variety of ceramic materials (traditional and hybrid ceramics) from various manufacturers: Dentsply Sirona, Ivoclar, Vita, 3M, Shofu Merz, GC, Coltene, Kurakay Noritake

- All cabinet indications, in blocks up to 70 mm; inlay, onlay, crowns, veneers, crowns screwed onto the implant, multilayer abutment, bridges – depending on the height of the cube/material

- Extra-Fine milling mode for a high level of detail in occlusal pits and interdental areas in the case of bridges

- Designed for speed and precision

- The Super Fast mode allows the milling of zirconium-based restorations in less than 5 minutes, reducing the processing time to more than half

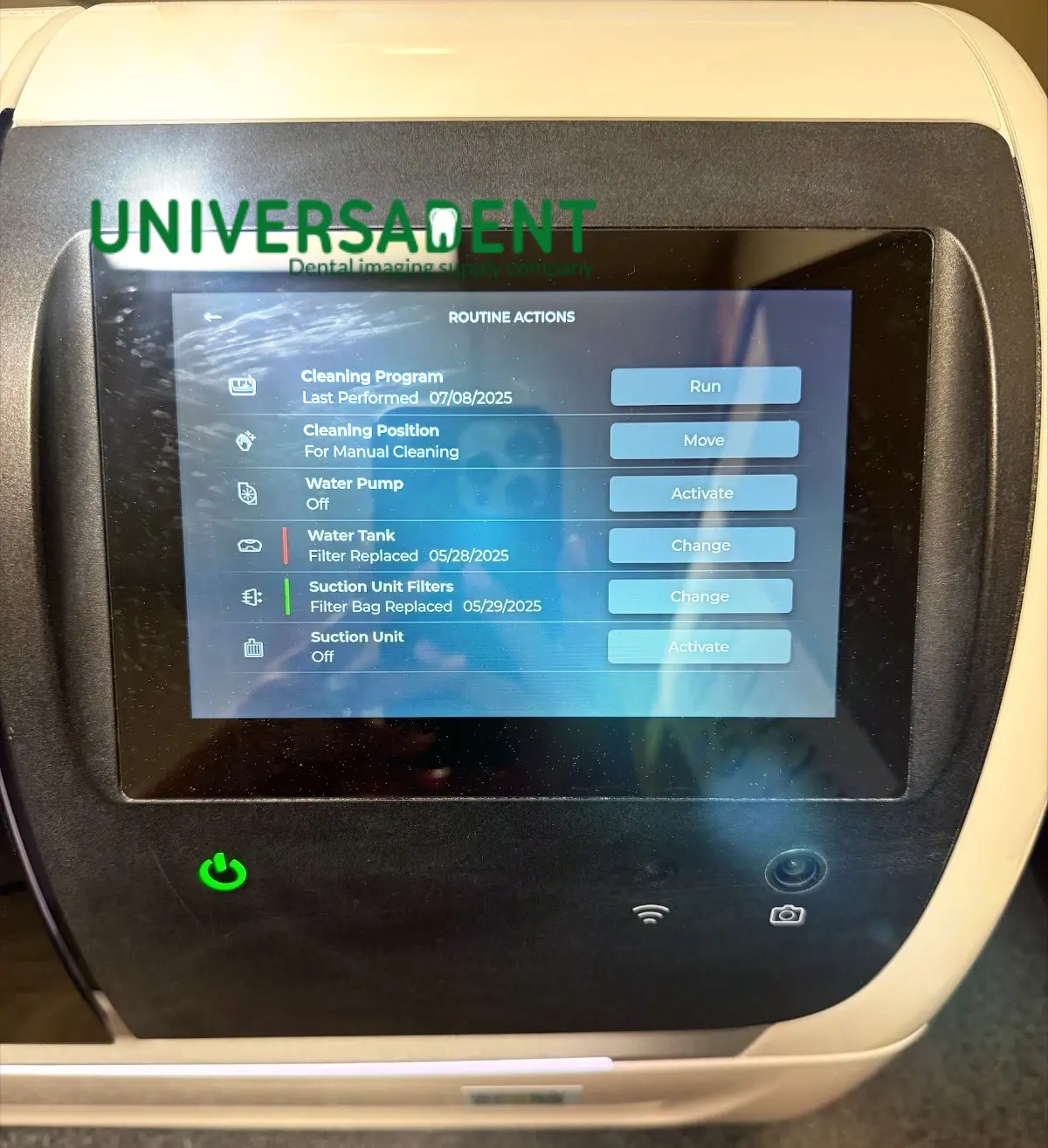

- The interactive interface guides the user step by step during the work process, as well as during maintenance procedures or other routine tasks

- The integrated cube scanner automatically scans material blocks with compatible data matrix codes, recording information such as type, size, color, or shrinkage factor for zirconium

- All milling tools for CEREC Primemill are equipped with a color-coded RFID chip, read by the RFID scanner, and can be monitored on the screen; the user is alerted in case of the need to replace a tool

- Ultra-fast milling function: full-contour zirconia crown in less than 5 minutes

- 7″ touch screen

- Scan QR code for CAD-CAM cubes

- RFID instrument reader

- Precise and fast milling/turning: full-contour zirconia crown turning in a maximum of 5 minutes with the fast milling function

- Improved milling strategies, precision, and adaptation with clinical results at the highest level

What’s new at the Primemill?

The features of the grinding and milling unit at a glance

- CEREC Primemill: wet-dry grinding and milling unit

- 7-Zoll Touch Interface.

- Super Fast mode for zirconia crowns.

- Block scanner and RFID tool reader for an easier and faster workflow.

- Complete range for various indications up to a block size of 70 mm.

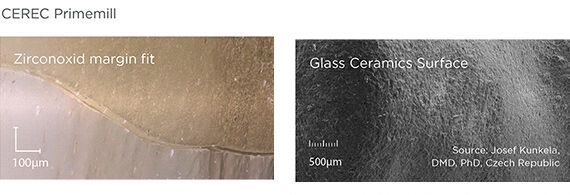

- Smoother surfaces in zirconia restorations.

CEREC Primemill produces restorations with clear margins and a very smooth surface resulting from the high-speed configuration with two axes and four motors. The product has a 7-inch touch interface, an integrated camera to scan blocks with compatible data matrix code, an RFID reader to read the tool information, and a modern and compact design that facilitates the operation.

The developers explain that when creating CEREC Primemill, special attention was paid to ease of use: the large touch interface guides the user through all workflow processes. In addition, restorations, especially zirconia restorations, can be milled faster due to new tools and improved technology.

The time required to fabricate a zirconia crown has been reduced by more than half: from 10-12 minutes to 5 minutes using the new ‘Super Fast’ mode. The complete system does not require any data import or export. All processes are coordinated and fully validated for a 100% integrated experience, which generates greater productivity through process standardization.

Speed

Engineered for speed and precision, the new CEREC Primemill inherits the proven strength of its predecessor and raises its robust performance to new heights.

You can now mill zirconia restorations in Super Fast milling mode in around 5 minutes, cutting processing times by more than half. The improved grinding method for high-quality glass ceramics also grinds the material faster than ever before result? Satisfied patients and increased productivity.

Quality

Combining new electronics, software, motors, and mechanical components contributes to more acceptable resolution and enhanced dynamics. This results in outstanding restoration margins and surface details – for exact results.

The new highly accurate 0.5 mm milling tool reliably delivers first-class clinical results. Switch to Extra Fine milling mode for more detail with occlusal fissures and interdental areas on bridges.

Versatility

Welcome to a world where you’re spoiled for choice! The new CEREC Primemill combines wet and dry milling and wet grinding. No matter the indication, with CEREC Primemill, you can select from a broad range of material options from validated partners providing the flexibility and predictability you need to offer patients the best possible treatment.

Choose from the full spectrum of machining options, including dry and wet milled zirconia or wet grinding of glass and hybrid ceramics.

Convenience

The new 7″ touch interface with user guidance guides operators step-by-step through the workflow, essential maintenance procedures, and other routine tasks so that you can delegate milling with complete peace of mind. The integrated block scanner is a time-saving new feature that automatically scans material blocks with compatible data matrix codes and records the information, including type, size, color, and zirconia enlargement factor.

All CEREC Primemill tools are fitted with a color-coded RFID chip that is read by the RFID tool reader, feeding into the tool status display, alerting the user if a device needs replacing. This ensures all tools are performing at optimal levels. A LED light strip indicates unit status and milling and grinding progress.

CEREC Primemill from the user’s point of view

Would you like to know how the Primemill performs from the user’s point of view? Dr. Gerhard Werling has been a convinced CEREC user and tester since the beginning.

What is interesting in his eyes is that the operation is much more elegant and comfortable again. For example, the Primemill recognizes the tools via an RFID reader and the blocks via a block scanner. This not only makes delegation particularly easy but also particularly secure.

The system is out of the nerdy habit that the CEREC community had many years ago. The devices and software can be operated intuitively without any prior knowledge. For example, the large 7-inch touch interface on the grinding machine for optimized operation and the scanners for detecting the blocks and grinding wheels.

The connection to commercial laboratories is also easier thanks to the opening of the CEREC system. Digitization started a long time ago in laboratories. The laboratories are certainly happy when they receive intraoral scans from practitioners with which they can continue working directly in their laboratory software.

– dr Gerhard Werling

Dentist and CAD/CAM user

In the eyes of Dr. Werling primarily practices with a very efficient, well-designed workflow. In these practices, the milling process can be prepared independently. This means that the machine can be equipped and adjusted in advance – keyword delegation – and the milling machine starts immediately when the practitioner presses the start button.

As an experienced CEREC user, Dr. Werling was particularly impressed by four new features when working with Primemill in his practice:

- Speed: A full zirconia crown can be milled in less than five minutes, and the edges and surfaces are of high quality simultaneously. This supports me eminently in my chairside workflow.

- Control: The Primemill can control drill bits or grinding tools because it records how long and how often they have already worked.

- Surface processing in fine mode: Beautiful chewing surfaces can be created with the device. This improves the function and aesthetics of the restoration even further.

- Flexibility: Another advantage is that the user can mill and sand dry and wet.

Package Include:

- CEREC Primemill basic device

- Including extensive accessories

- CEREC PRIMILL DIAMOND CUTTER 1.4CS CX6

- CEREC PRIMILL DIAMOND CUTTER 1,2CS CX6

- CEREC PRIMILL DIAMOND CUTTING CUTTER 1.0CS CX6

- CEREC PRIMILL DIAMOND CUTTER 0.6CS CX6

- CEREC PRIMILL BUR 2.5 ZRO2 CS CX3

- CEREC PRIMILL BUR 2.5 PMMA CS CX3

- CEREC PRIMILL BUR 1.0 CS CX3

- CEREC PRIMILL BUR 0.5 CS CX3

- CAM software instruction in connection with the device instruction, flat rate

- Delivery, setup, installation and technical device instruction, flat rate

- CEREC suction for CEREC Primemill

- Water tank (in unit) with filter cartridge

- adapter sleeve

- Removal tool for adapter sleeve

- calibration set

- torque wrench

- Torque wrench HT

- pressure screw, 3x

- Starter set Diamond CS

- Starter set Bur CS

- Technical Documentation

- power cord

- Crossover cable (LAN) 10 m

- block clamping tool

- Dentate 1000ml

- Water tank filter, packed separately

- gas cap opener

- cleaning set

- sieve insert

- O-rings, 3x

- Celtra Duo starter set

Technical data CEREC Primemill

- Type designation: CEREC Primemill or CEREC Primemill US

- Rated mains voltage: 100V – 240V ~

- Rated grid frequency: 50/60 Hz

- Rated Current: 2.1-4.2A

- Rated power: 400VA

- Permissible mains voltage fluctuations: ±10% of the nominal voltage

- Type of protection against electric shock: Device of protection class I

- Degree of protection against ingress of water: ordinary device (without protection against ingress of water)

- Overvoltage category II

- Environmental Conditions: Indoor use

- Pollution degree 2

- Air Pressure: 700hPa – 1060hPa

- Temperature range: 5°C to 40°C

- Humidity range: 80% rel. Up to 31°C decreasing to 50% rel. up to 40°C

- Operating mode: continuous operation

- Radio frequency band: 13.553 MHz – 13.567 MHz

- Maximum transmission power: < 200 mW

- Dimensions W x H x D in mm: 729 x 454 x 465

- Weight, about 46 kg